Exploring the Key Considerations When Buying Remanufactured Engines

Introduction to Remanufactured Engines

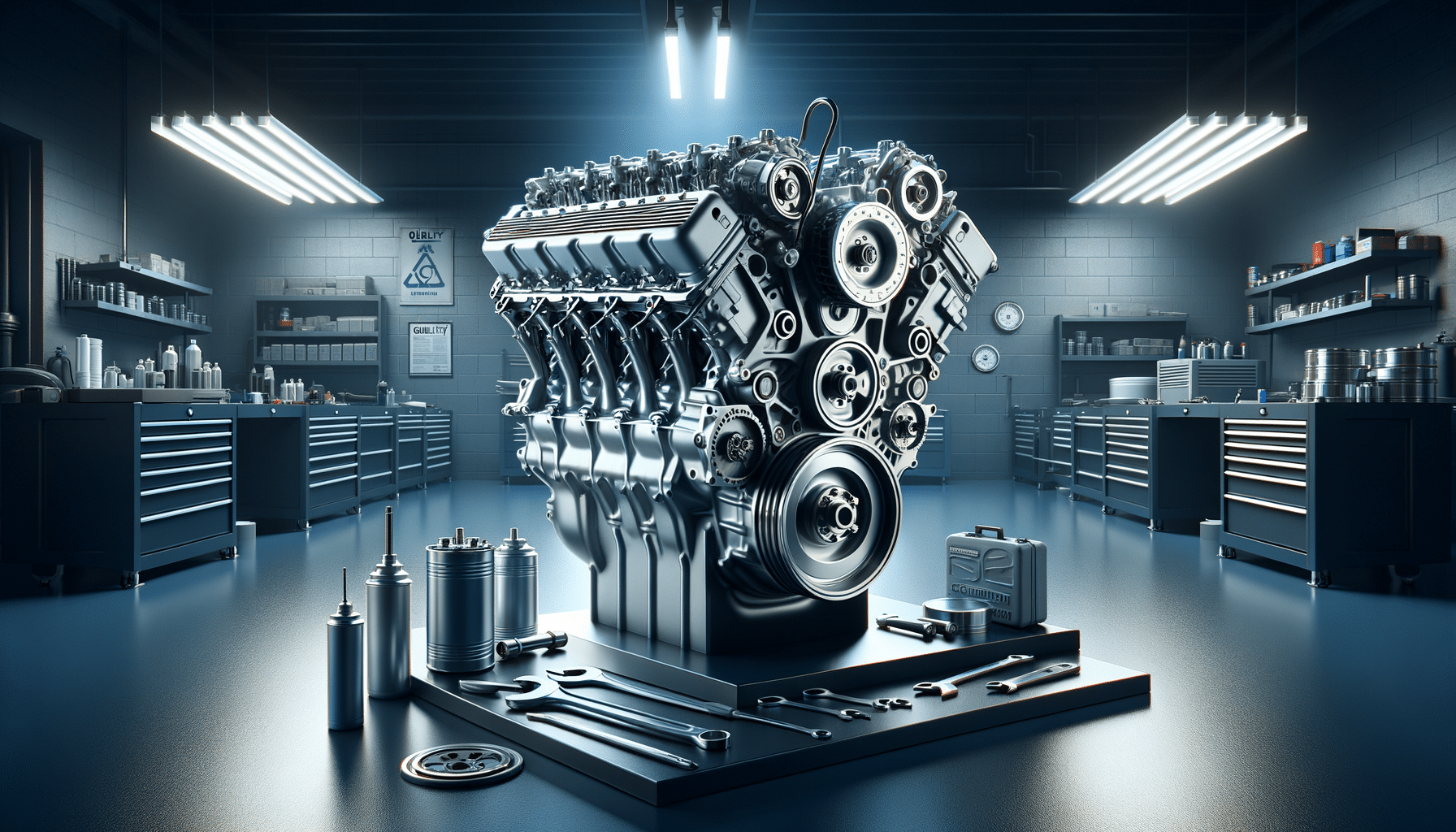

In the world of automotive repairs, remanufactured engines have become a popular choice for those seeking to replace their vehicle’s engine without the cost of a brand-new unit. These engines are not simply repaired but are rebuilt to meet or exceed the original specifications. This means they can offer a reliable and cost-effective solution for extending the life of a vehicle. However, purchasing a remanufactured engine requires careful consideration to ensure you get a product that offers both quality and value.

Understanding the Remanufacturing Process

The remanufacturing process involves taking a used engine and restoring it to a like-new condition. This is achieved by disassembling the engine, cleaning all components, and replacing worn or damaged parts. Critical components such as pistons, bearings, and gaskets are typically replaced with new ones. The engine is then reassembled and tested to ensure it meets the necessary performance standards. This rigorous process ensures that the engine performs reliably, often with a warranty comparable to new engines.

Key considerations during this process include:

- Quality of replacement parts used

- Testing procedures for performance and reliability

- Warranty terms offered by the remanufacturer

Understanding these aspects can help you evaluate the quality of a remanufactured engine and make an informed purchasing decision.

Evaluating the Supplier

Choosing the right supplier is crucial when purchasing a remanufactured engine. A reputable supplier will provide detailed information about their remanufacturing process, the quality of parts used, and the testing procedures they implement. It is important to research the supplier’s reputation, looking for reviews or testimonials from previous customers. A well-regarded supplier is more likely to offer engines that deliver reliable performance.

Consider the following when evaluating suppliers:

- Certifications and industry affiliations

- Customer service and support

- Transparency in their processes and practices

By taking these factors into account, you can increase the likelihood of purchasing a remanufactured engine that meets your expectations.

Cost Considerations

One of the primary reasons for choosing a remanufactured engine is cost savings. These engines are generally more affordable than new ones, making them an attractive option for budget-conscious consumers. However, it’s essential to weigh the initial cost against the potential long-term benefits and savings. A cheaper engine may not always be the most cost-effective choice if it lacks reliability or comes with a limited warranty.

Key cost-related factors include:

- Price comparison with new and used engines

- Warranty coverage and potential repair costs

- Fuel efficiency and performance improvements

By considering these elements, you can determine whether a remanufactured engine offers true value for your investment.

Conclusion: Making an Informed Decision

Purchasing a remanufactured engine can be a practical and economical choice for vehicle owners looking to extend the life of their cars. By understanding the remanufacturing process, evaluating suppliers, and considering cost implications, you can make an informed decision that balances quality, reliability, and affordability. As with any significant purchase, thorough research and careful consideration of all factors will help ensure that you select an engine that meets your needs and expectations.