A Guide to Buying Remanufactured Engines: Important Factors to Consider

Introduction to Remanufactured Engines

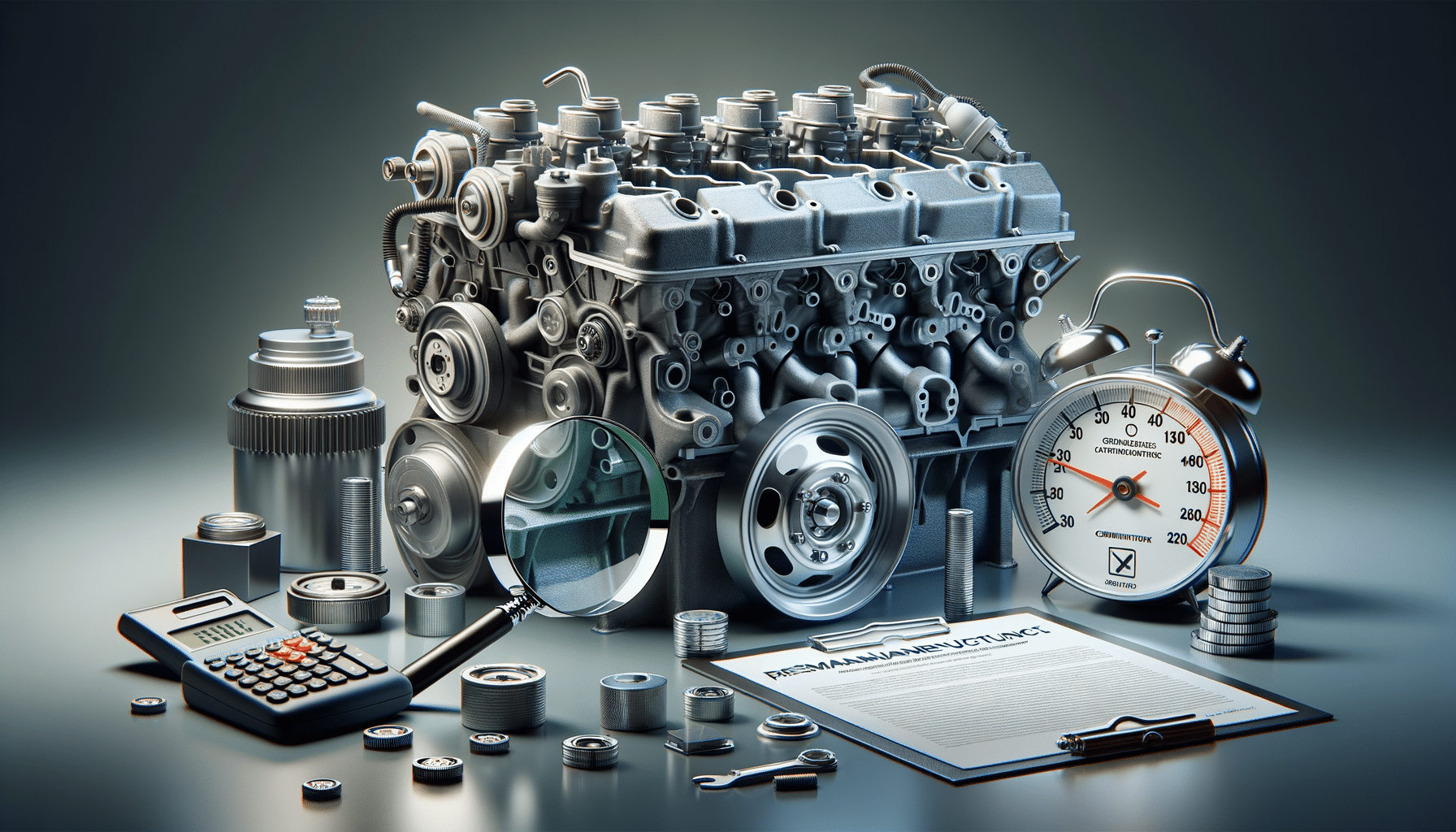

In the ever-evolving world of automotive repairs and maintenance, remanufactured engines have emerged as a viable option for many vehicle owners. These engines, which are essentially rebuilt to meet original equipment manufacturer (OEM) specifications, offer a cost-effective and environmentally friendly alternative to new engines. Understanding the importance of choosing the right remanufactured engine is crucial, as it directly affects the performance, reliability, and longevity of your vehicle.

Remanufactured engines are not simply repaired; they undergo a rigorous process where worn or outdated components are replaced or restored to ensure optimal functionality. This guide aims to provide you with a comprehensive understanding of the factors to consider when purchasing a remanufactured engine, ensuring that you make an informed decision.

Understanding the Remanufacturing Process

The remanufacturing process is a meticulous and detailed procedure that involves disassembling the engine, cleaning all parts, and replacing or refurbishing components as needed. This process ensures that the engine is restored to a condition that is comparable to a new engine. Key steps in the remanufacturing process include:

- Inspection and Disassembly: Each component of the engine is thoroughly inspected to identify wear and damage. The engine is then disassembled for further analysis.

- Cleaning and Machining: Parts are cleaned using specialized equipment to remove dirt, grease, and contaminants. Machining processes are employed to restore parts to their original specifications.

- Replacement and Reassembly: Worn-out parts are replaced with new or refurbished ones. The engine is then reassembled, ensuring all components are correctly aligned and functioning.

- Testing and Quality Control: The remanufactured engine undergoes rigorous testing to ensure it meets OEM standards. Quality control checks are performed to verify performance and reliability.

Understanding this process is crucial when assessing the quality of a remanufactured engine. A well-executed remanufacturing process can significantly enhance the engine’s performance and durability.

Factors to Consider When Buying a Remanufactured Engine

When purchasing a remanufactured engine, several factors should be taken into account to ensure you make a well-informed decision. These factors include:

- Warranty: A comprehensive warranty provides peace of mind and protection against potential defects. Ensure that the remanufacturer offers a warranty that covers a reasonable period and mileage.

- Reputation of the Remanufacturer: Research the remanufacturer’s reputation by reading reviews and seeking recommendations. A reputable remanufacturer will have a track record of producing reliable and high-quality engines.

- Compatibility: It is essential to ensure that the remanufactured engine is compatible with your vehicle’s make and model. Compatibility issues can lead to performance problems and additional costs.

- Cost: While remanufactured engines are generally more affordable than new ones, prices can vary. Compare prices from different suppliers to find a competitive deal without compromising on quality.

By considering these factors, you can select a remanufactured engine that meets your needs and enhances your vehicle’s performance.

Comparing Remanufactured and Rebuilt Engines

When exploring engine replacement options, it’s important to understand the difference between remanufactured and rebuilt engines. Although these terms are often used interchangeably, they refer to distinct processes with varying outcomes.

Remanufactured Engines: As previously discussed, remanufactured engines are restored to OEM specifications through a comprehensive process that includes replacing worn components and rigorous testing. These engines are essentially as good as new, offering reliability and performance akin to a new engine.

Rebuilt Engines: Rebuilt engines undergo a less extensive process, where only the faulty components are replaced or repaired. While this can be a cost-effective solution, rebuilt engines may not offer the same level of reliability and longevity as remanufactured engines.

In summary, remanufactured engines are generally a more reliable option due to the thoroughness of the remanufacturing process. However, the choice between remanufactured and rebuilt engines ultimately depends on your budget, vehicle requirements, and long-term goals.

Conclusion: Making an Informed Decision

Choosing the right remanufactured engine is a crucial decision that can significantly impact your vehicle’s performance and longevity. By understanding the remanufacturing process, considering key factors such as warranty and reputation, and comparing your options, you can make an informed choice that aligns with your needs and budget.

Remanufactured engines offer a cost-effective and environmentally conscious alternative to new engines, making them an attractive option for many vehicle owners. By taking the time to research and evaluate your options, you can ensure that you select a high-quality remanufactured engine that will serve you well for years to come.